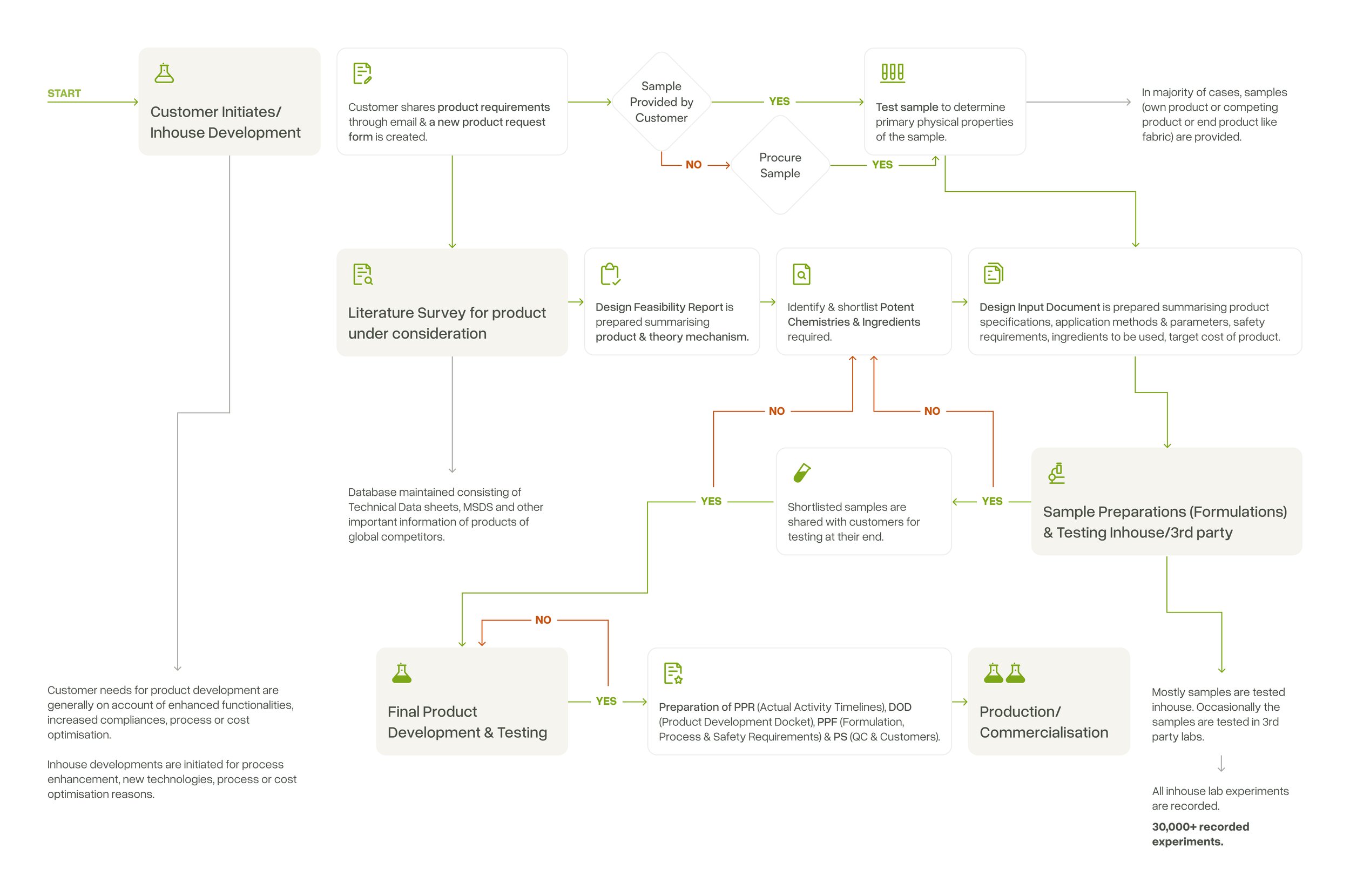

Understanding Our Process

The product development and innovation process at LN Chemicals is structured to ensure effective collaboration with customers and efficient creation of new chemical products. Below is a detailed overview of their approach based on the provided information.

STEP 01

-

LN Chemicals initiates the product development process by closely collaborating with customers to understand their specific requirements. This engagement is crucial for aligning development efforts with market needs.

STEP 02

-

The R&D team focuses on two primary objectives: developing new products and continuously improving the quality and performance of existing products. This involves conducting thorough literature surveys and maintaining a database of technical data sheets and safety information.

STEP 03

-

A feasibility study is conducted to assess the technical, economic, and environmental viability of the proposed product. This includes evaluating raw material availability, production costs, and compliance with regulatory requirements.

STEP 04

-

If a customer provides a sample, LN Chemicals tests it to determine its physical properties. This step is essential for identifying suitable chemistries and ingredients for product formulation.

STEP 05

-

A Design Input Document is prepared, summarizing product specifications, application methods, safety requirements, and target costs. This document serves as a guideline for the development process.

STEP 06

-

The team identifies and shortlists potential chemistries and ingredients for the product formulation. Samples are prepared and tested either in-house or at third-party laboratories.

STEP 07

-

Shortlisted samples are shared with customers for testing. Customer feedback is integral to refining the product and ensuring it meets their expectations.

STEP 08

-

LN Chemicals maintains a comprehensive record of in-house laboratory experiments, which aids in optimising formulations and enhancing product quality. Over 30,000 experiments have been documented, reflecting the company's commitment to innovation and quality assurance.

STEP 09

-

The development process adheres to stringent regulatory standards to ensure safety and environmental protection. Necessary permits and approvals are obtained from relevant authorities before proceeding to production.

STEP 10

-

A robust quality control program is established to monitor product quality throughout the manufacturing process. This includes testing raw materials, in-process checks, and final product evaluations to ensure compliance with specifications.

STEP 11

-

Successful pilot-scale production leads to full-scale manufacturing. The production facility is designed to optimise efficiency while meeting regulatory standards.

[ TO CONCLUDE ]